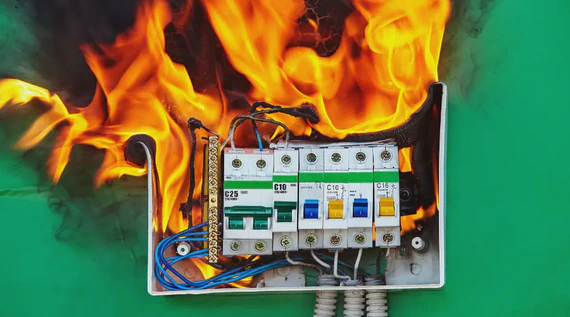

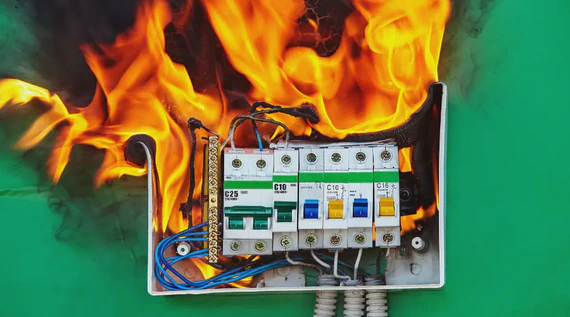

Flame Retardants — The Chemistry That Saves Lives

Fire safety is not just a regulatory requirement — it’s a life-saving necessity. Every year, countless incidents are …

Every pellet that leaves a compounding line carries more than color or additive—it carries precision chemistry designed to protect polymers from heat, oxidation, and time.

In film extrusion, molding, or piping, oxidation is the silent destroyer. It weakens polymer chains, dulls appearance, and shortens product life.

That’s where antioxidant masterbatches step in — engineered to safeguard polymers at the molecular level and ensure performance that lasts.

When polymers are exposed to heat, oxygen, or UV radiation, free radicals begin attacking the molecular chains.

This leads to chain scission, discoloration, loss of tensile strength, and eventually — failure of the material.

Common oxidation triggers include:

Without stabilization, even the highest-grade polyethylene or polypropylene will degrade during its life cycle.

Antioxidant masterbatches are not a single chemical solution. They’re carefully formulated blends of stabilizers designed to work together at different stages of degradation.

Primary antioxidants — such as hindered phenols — act as free radical scavengers.

They capture radicals the moment they form, stopping the oxidation chain reaction before it grows.

Secondary antioxidants — like phosphites and thioesters — target hydroperoxides, converting them into harmless molecules while regenerating primary antioxidants.

Together, they create a synergistic stabilization system that offers both immediate protection during processing and long-term stability in use.

Creating an antioxidant masterbatch involves more than mixing chemicals — it’s about achieving uniform dispersion, compatibility, and long-term activity.

Our R&D teams begin by selecting a base polymer carrier that matches the target resin (for example, PE-based carriers for PE films).

The antioxidants are compounded under controlled conditions to prevent premature reactions and ensure optimal distribution within every pellet.

Parameters such as melt flow index, thermal profile, and shear rate are fine-tuned so that the antioxidants are active when needed — during processing and throughout product life.

Each batch is then granulated and quality-checked to maintain visual uniformity, dispersion quality, and additive consistency.

Performance validation is at the core of every formulation.

Before reaching the customer, each antioxidant masterbatch undergoes a battery of analytical and performance tests, including:

These tests provide both quantitative data and field confidence, ensuring that every pellet performs predictably in production.

Designed specifically for agricultural film applications, AD 55 delivers long-term oxidation resistance in outdoor environments.

By reducing chain scission and discoloration, it extends film life even under continuous UV exposure and fluctuating temperatures.

AD 55 helps films retain mechanical strength, flexibility, and optical clarity throughout multiple crop cycles — ensuring reliable protection in the field.

A versatile grade suited for films, molding, and general-purpose applications, PE 1031 prevents oxidation and yellowing during processing and storage.

It offers balanced stabilization, making it ideal for converters seeking cost-effective thermal protection across multiple polymer types.

Developed for PPR piping systems, P 1033 provides long-term thermal stabilization, ensuring the material maintains its integrity under continuous hot-water conditions.

This formulation prevents oxidation-induced failures in plumbing and industrial piping networks.

Every antioxidant masterbatch formulation is the result of deep polymer chemistry and disciplined process control.

From lab-scale development to full-scale compounding, every step is governed by one goal:

consistent performance and predictable stability.

By investing in advanced testing, real-time monitoring, and field validation, we ensure that our products perform not just in controlled conditions — but in real-world environments where it matters most.

Inside every pellet lies precision-engineered chemistry — designed to protect polymers from the invisible forces that age and weaken them.

Our antioxidant masterbatches, including AD 55, PE 1031, and P 1033, are built to deliver stability, clarity, and confidence across films, molding, and pipe applications.

Because true performance doesn’t just come from the polymer — it’s engineered inside the pellet.

Fire safety is not just a regulatory requirement — it’s a life-saving necessity. Every year, countless incidents are …

Introduction Black masterbatch plays a vital role in the film industry — not just for coloration, but for enhancing …

With 80,000 MTA capacity and world-class manufacturing across India, Sonali delivers plastic solutions trusted around the globe.

Contact Us